Adidas is set to release the Climacool “Off White” on May 2, 2025, marking a significant milestone in footwear manufacturing. The sneaker, priced at $140, will be available through the Adidas Confirmed app and at select stores across New York, Miami, Chicago, Los Angeles, and Las Vegas. Plans for international distribution have not been finalized.

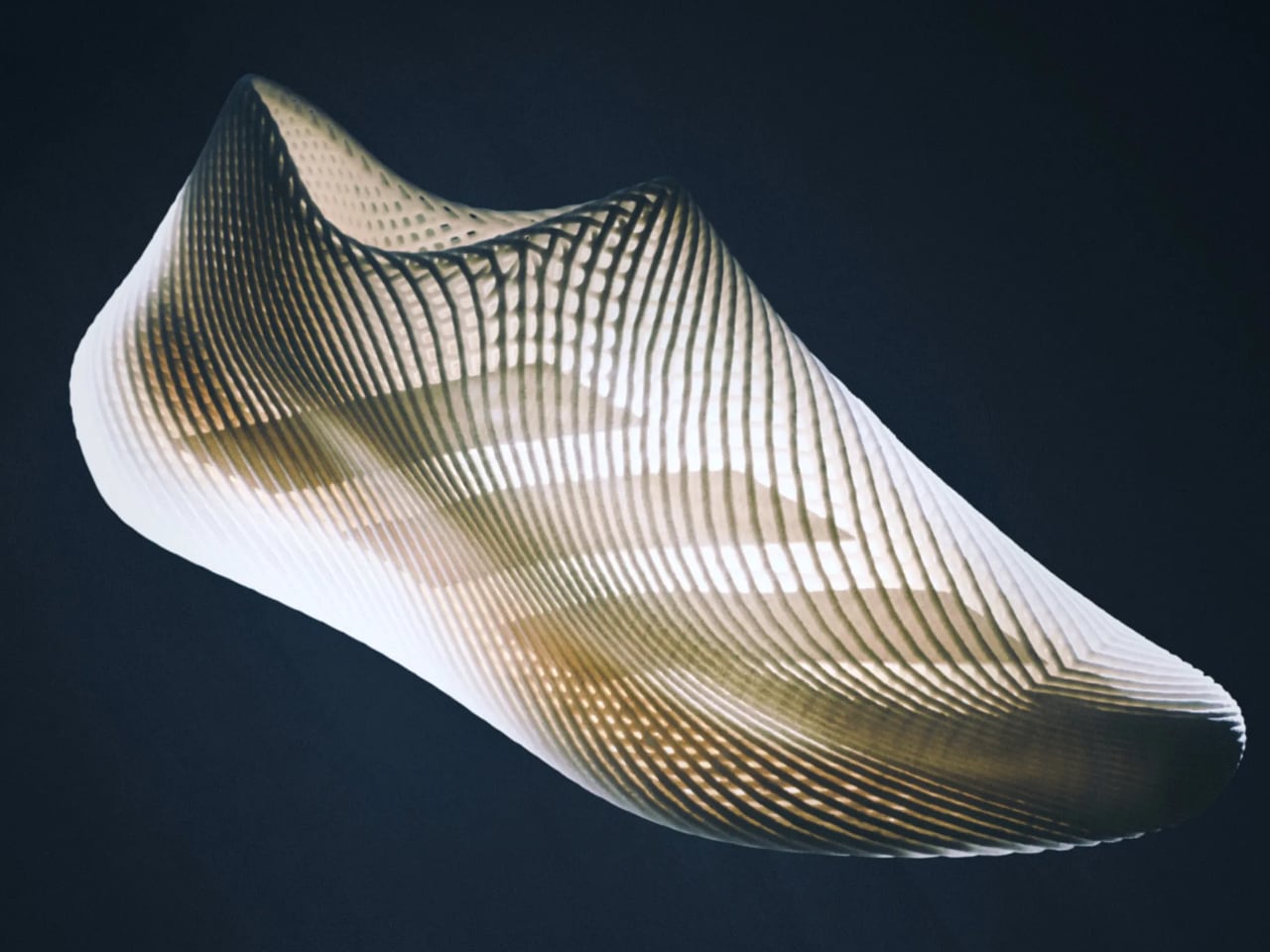

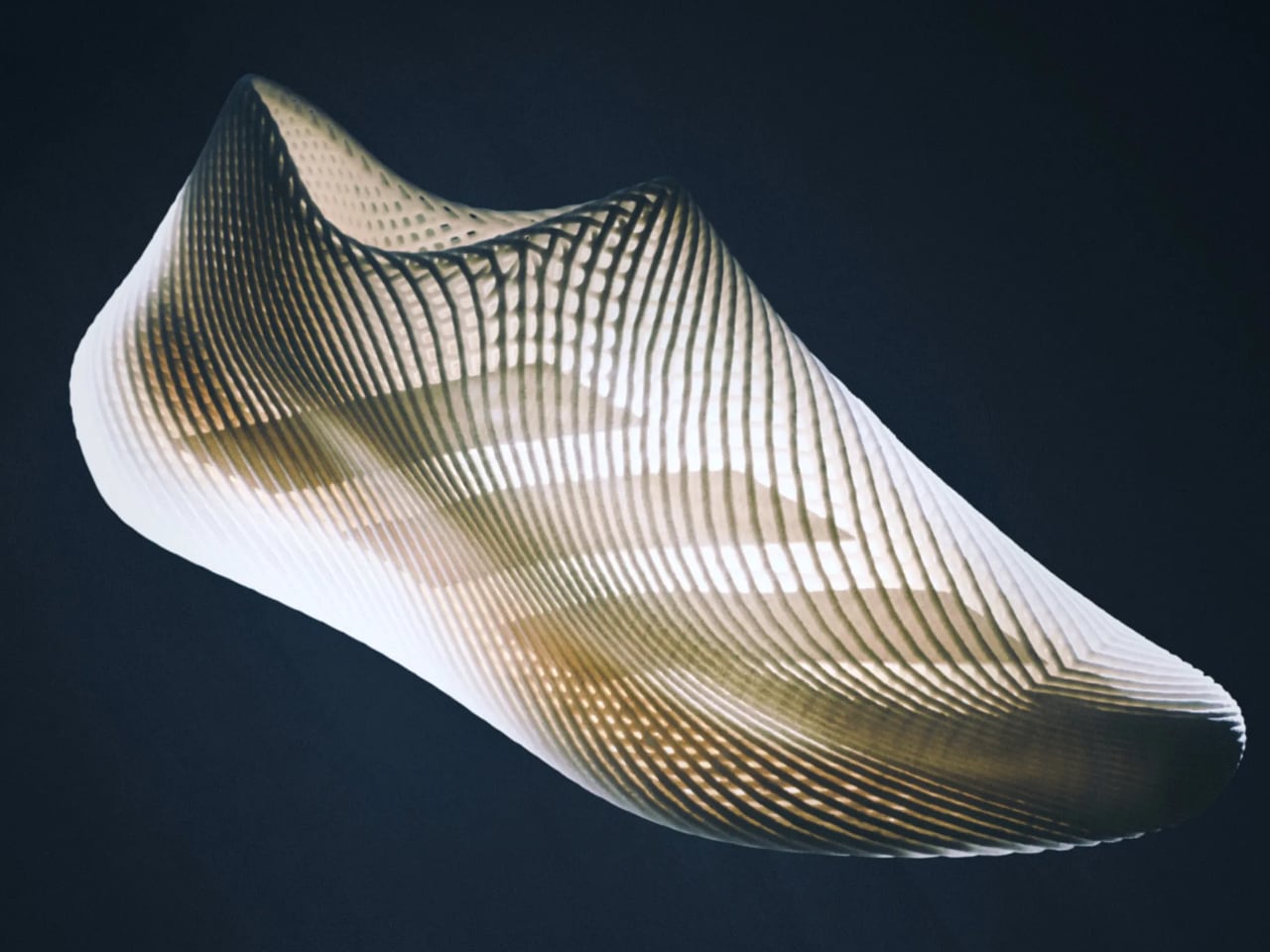

The Adidas Climacool moves beyond previous 4D models by delivering a sneaker that is entirely 3D printed, from the upper to the sole. The construction uses an intricate open lattice structure designed to provide 360-degree breathability while maintaining a lightweight profile. Every element of the shoe, including built-in arch support and cushioned heel zones, is printed directly into the form without the need for traditional stitching or assembly.

Breathing Through Every Cell

Adidas moved beyond partial experiments with the Climacool. Previous designs introduced printed midsoles, but the Climacool reimagines the entire structure. A complex, open lattice stretches uninterrupted across the shoe, allowing air to circulate freely through the body.

The minimalist slip-on profile eliminates traditional laces and features a creamy off-white color that softens the intricate geometric surface. Bold three-stripe branding runs across the side, blending the company’s legacy elements into a futuristic frame.

Support structures are embedded directly into the printed form. Subtle arch support rises underfoot, while additional cushioning around the heel ensures comfort without relying on separate inserts or padding layers.

Additive Manufacturing and Adidas’ Evolution

Adidas has spent more than a decade refining its approach to 3D-printed footwear, laying the groundwork for the Climacool’s full-scale debut. Early experiments with limited-edition Futurecraft 4D models introduced Digital Light Synthesis technology, a process that uses UV light to transform liquid resin into detailed, flexible lattice structures. These first steps demonstrated the potential of additive manufacturing, but applications remained partial, limited mostly to midsoles rather than full footwear assemblies.

The Climacool moves this vision forward. Produced through a layer-by-layer printing process, the sneaker achieves a seamless, one-piece form that dramatically reduces the number of manufacturing steps required compared to traditional methods. This approach also minimizes material waste, since every portion of the shoe’s structure is precisely built rather than cut or stitched from larger materials.

Although additive manufacturing supports possibilities for custom-fitted footwear, the Climacool release is offered only in standard sizing. Adidas has opted to focus on broader accessibility for this launch rather than pushing individualized production at scale.

While other brands such as Nike and New Balance have explored 3D printing with projects like the Air Max 1000 and Formlabs collaborations, their efforts have remained centered on specific components rather than entire shoes. The Climacool stands apart by delivering a fully 3D-printed sneaker designed for general consumer availability.

By bringing a complete 3D-printed design to mass production, Adidas signals a pivotal shift in how performance footwear could be designed, manufactured, and distributed in the future.

Design and Market Significance

The physical structure of the Climacool reveals how form follows function. The lattice system breathes naturally, providing constant airflow without adding bulk or stiffness. This structure enables improved comfort in warm conditions, making the shoe especially suitable for sockless wear.

The slip-on silhouette further simplifies daily use. Without a separate tongue or traditional lacing system, the Climacool maintains a consistent fit and streamlined profile from heel to toe. The integrated support zones, built into the printed body, add structure where needed without relying on glued or sewn parts.

Visually, the Climacool strikes a balance between complexity and restraint. From a distance, the creamy, off-white surface appears minimal and aerodynamic. Up close, the layered lattice reveals intricate geometric patterns that shift in response to movement and changing light.

The Climacool’s launch points to broader possibilities in sustainable manufacturing. By reducing the number of production stages and minimizing excess material, additive manufacturing offers a more efficient and flexible approach to future footwear creation.

Adidas’ full-scale 3D-printed sneaker represents a new benchmark. Climacool marks the point where advanced technology meets real-world wearability, opening the door for a new generation of athletic and lifestyle footwear built for performance, comfort, and environmental responsibility.